Perform a quick online search on the term ‘order management’ and almost all results returned provide a definition of order management systems (OMS) in the context of eCommerce. No doubt order management visibility for eCommerce is quite well-established. This occurs even on a global scale where product visibility from order placement (with overseas suppliers) to in-transit visibility to delivery is provided by many platforms – either direct to the consumer or to fulfillment centers.

This article shines a light on a different kind of order management; these are for products that fill that big box store in your neighborhood along with most of the stores in the shopping plazas across neighborhoods and cities.

Order Management for Global Supply Chains

The order management processes covered here relate to the kind used by large corporations and involve demand planning, procurement, order placement, logistics, distribution, finance, and much more. Given that cargo is crossing borders, that brings in export and import compliance, along with the logistics complexities that come with it.

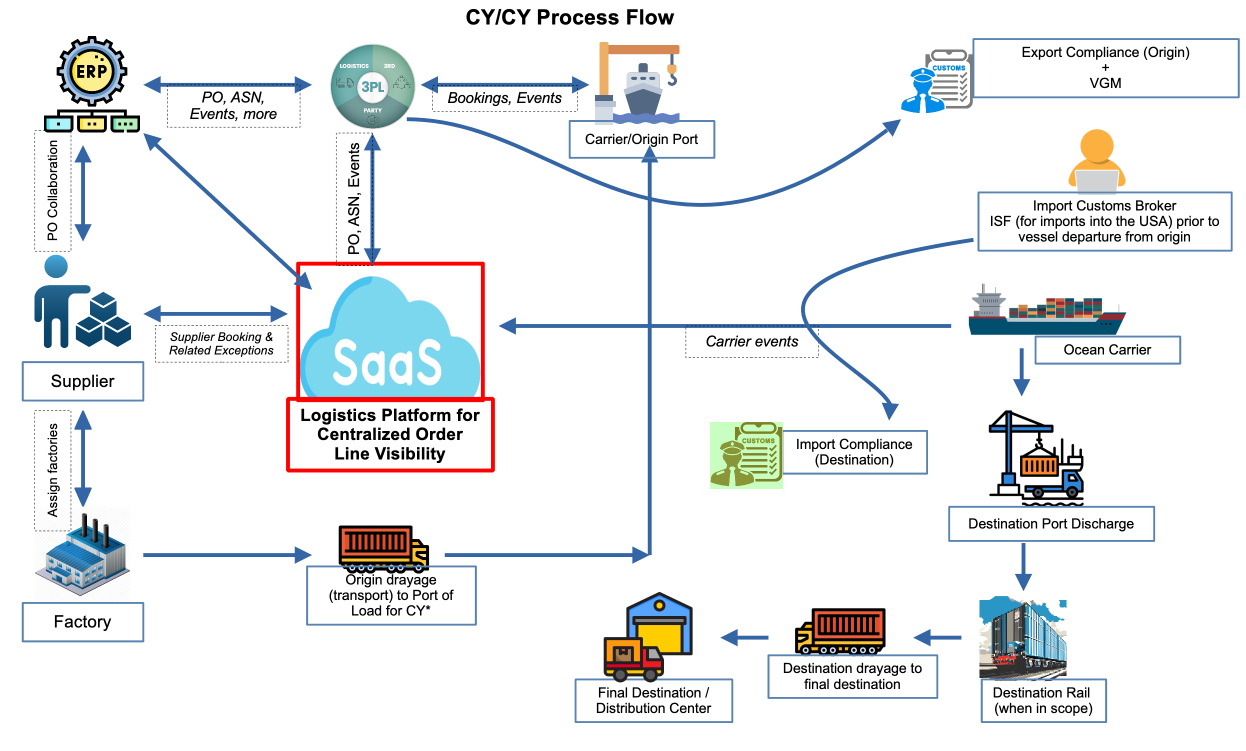

The below two process flows show how information (and yes, integration) flows and how they touch many different software applications.

In a CFS/CY process flow (Container Freight Station to Container Yard), where cargo is consolidated and stuffed into a container at origin for a single importer of record, there is an added step of consolidation at the origin CFS (between the factory and the origin port).

Nearly all the blue arrows shown in the above flows require underlying integrations to ensure all parties in the supply chain (or what Brittain Ladd aptly suggests should be called a “supply web”) always remain informed about cargo status.

Below are the primary parties depicted in the flow

- Buyer (Importer of Record)

- Supplier (sometimes known as vendor)

- Manufacturer (this may or may not be the same as the supplier)

- Note: a single purchase order may consist of multiple order lines, each produced by a different manufacturer.

- 3PL or LSP – This is typically the party coordinating movement of cargo with the steamship line.

- Ocean Carrier – this is the steamship line (e.g., Maersk, Evergreen) physically transporting the container(s).

- Drayage (from place of receipt to origin port and from discharge port to place of delivery) - depending on the shipping arrangement the 3PL may be responsible for providing status visibility to these legs of the shipment.

- In many cases the drayage at destination is owned and provided by a separate party, who is responsible for providing shipment events required by the buyer.

- There are SaaS platforms that have built technology to provide visibility to this leg of the shipment using location tracking. (Drayage visibility will be covered in a future article).

- Customs Broker at destination – This party may or may not be the same as the 3PL and is responsible for ensuring compliance at destination. This includes filing the import entry with customs authorities. For shipments entering the US, the customs broker ensures that the ISF is filed no later than 24 hours prior to vessel departure from origin.

- Rail - when the place of delivery of a container is too far inland from the port of discharge, it is often moved via rail, which is far more economical than shipping by road. Rail transport is only used for full container (CY/CY) movements. The primary organization providing statuses for rail movements is Railinc.

Purchase Order (PO) Line Visibility

Once a supplier is selected to manufacture a product, the buyer and seller begin collaborating on key details such as quantity, unit cost, and delivery dates, which can mean delivery dates to the final destination or the origin port. A single purchase order may include multiple delivery dates for different order lines, though buyers sometimes choose to create separate purchase orders instead. Another common approach is the use of blanket purchase orders and release purchase orders within ERPs, which will be discussed separately.

Purchase order collaboration can take place over the phone, via email, or through an online SaaS platform such as Infor Nexus. Typically, an integration is required to provide the buyer’s ERP with the final, agreed-upon version of the purchase order.

After the purchase order is finalized, the supplier begins the process of fulfilling the order. Below are areas of the Purchase Order lifecycle that usually require integration.

| Message Type | Scenario / Description | Sender | Receiver |

|---|---|---|---|

| New Purchase Order | Initial version of PO | Buyer | 3PL and/or Supplier |

| Purchase Order Acknowledgement | When a PO is received from the buyer the first time | 3PL and/or Supplier | Buyer |

| Purchase Order Changes | These include updating quantities, ship dates and other fields of a purchase order line | Buyer | 3PL and/or Supplier |

| Supplier Bookings | When the supplier books PO lines for shipping with the 3PL | 3PL | Buyer |

| Warehouse Receipt | In the case of consolidation of cargo at the origin (CFS) facility | 3PL | Buyer |

| ASN | Upon departure of vessel | 3PL | Buyer |

| Shipment Statuses | Critical component of any shipment | 3PL and any assigned carriers | Buyer and/or Logistics Platform |

Below are a few more details on some of the integrations listed above

- Purchase Order Changes may include -

- Removing one or more purchase order line

- Updating Purchase Order header information such as ship to address, payment terms, shipment terms, etc.

- Supplier Bookings – when the supplier books cargo with the assigned freight-forwarder, they often create a booking on the logistics platform. Integration may be needed for the following -

- An inbound booking message from the supplier

- Informing the buyer that a supplier has submitted a booking

- Informing the buyer of booking exceptions (in case of supplier over or under-booking, though such exceptions are best managed and resolved on the logistics platform

- Warehouse Receipts – In the case of consolidation of cargo at the origin container freight station (CFS) facility, the 3PL provides a notification of receipt of cargo from each supplier against a PO.

- Advance Shipment Notification (ASN) - This message is usually sent when the vessel carrying the container has departed the origin port of load.

- Shipment Statuses – This is a critical component of any shipment (domestic or international). The buyer defines the statuses and the sequence in which they must be sent by the NVOCC and/or the entity providing the purchase order management service.

- Note that shipment statuses are commonly sent for all shipments whether or not PO management is used.

The above isn’t a finite list of integrations, and there could be more depending on the complexity and requirements of the business. Other common integrations used in global logistics are -

- Security filing for imports into a country (e.g., ISF for US-bound ocean shipments).

- A full list of (order) lines contained in a shipment. This may be sent to the customs broker responsible for filing the entry with a country’s customs authority. This message is used by the customs broker to accurately file the entry and also prevent manual data entry. In the USA Customs and Border Protection requires a Prep 7501 (Entry Summary) filing for every import shipment.

- When Transload is involved at the destination. This refers to the process of transferring goods from one mode of transportation to another during their journey – e.g., when a large retailer wants to break down the contents of a container for further distribution to individual retail stores.

Conclusion

One of the key advantages of purchase order (PO) management is the ability of a SaaS logistics platform to present detailed supplier booking and shipment information for each order line—including which container a line is assigned to and the percentage of the order that remains un-booked for shipping by the supplier. This level of visibility allows buyers and importers to monitor the status of every order line across hundreds or even thousands of purchase orders, enabling better planning for downstream deliveries to customers or retail locations.